Third of five paperChain project demo-cases begins in Slovenia

Third of five paperChain project demo-cases begins in Slovenia

paperChain—the collaborative research and innovation project funded under the European Union´s H2020 programme, and coordinated by Acciona Construction—began the demonstration of its first circular-case in October.

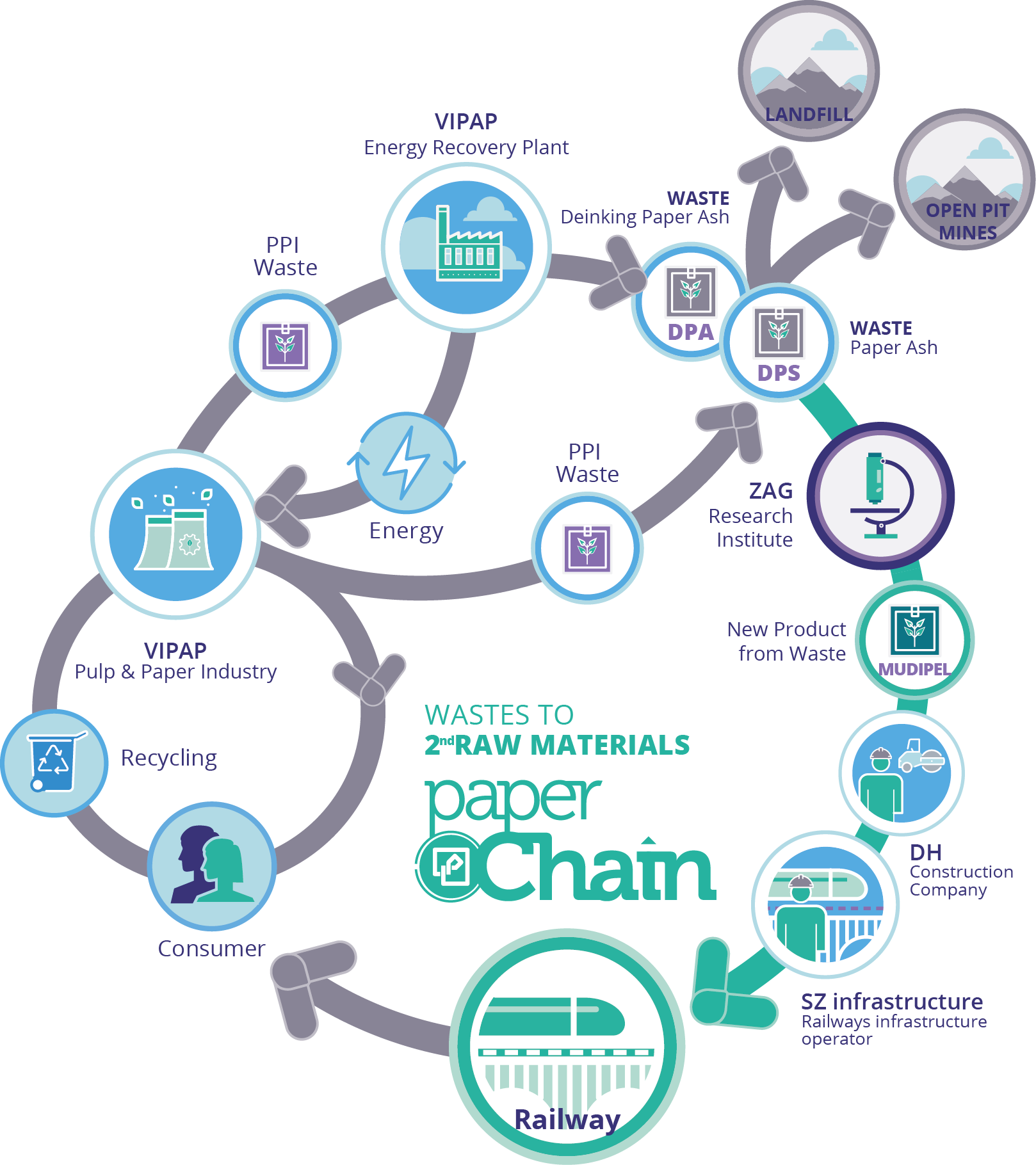

The paperChain Project “New Niche Markets for Pulp and Paper Industry Waste based on circular economy approaches” seeks to demonstrate the technical and environmental feasibility (TEF) of using different streams—generated in the Pulp & Paper Industry—as a secondary raw material, with the aim of obtaining competitive substitutes for primary raw materials in the near future.

This Project includes five large-scale demonstrators or demo-cases in different operational environments: Construction in Portugal (asphalt mixtures and concrete in roads), Spain (stabilised-soil layers in roads) and Slovenia (composite materials for landslide stabilization near railway lines); Chemical industry in Sweden (bio-ethanol for secondary chemicals); and Mining in Sweden (sealing layers for reactive spoil).

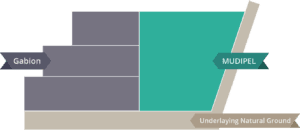

In specific terms, the Slovenian demo-case will be demonstrating the use of MUDIPEL material (deinked paper ash and sludge) generated in the waste-to-energy plant of VIPAP VIDEM KRŠKO d.o.o, located in the municipality of Novo mesto. These ashes (currently a material of no useful value) would replace back–fill virgin gravel prior to the construction of retaining walls. Gabion-type retaining walls will be constructed.

Landslides often threaten railway lines in mountainous countries such as Slovenia. Unstable blocks of rock represent a risk in terms of rock-falls, which could happen at any time and interrupt rail traffic and endanger the lives of passengers. Railway operators need a simple solution for the renovation of unstable slopes near railway lines. The solution with gabions and recycled MUDIPEL material enables stabilization of smaller unstable slopes in a short time. Instead of virgin gravel, recycled MUDIPEL material is used. MUDIPEL has much better strength properties than gravel, making construction of gabions more cost-effective. At least 30 % fewer gabions could be used by replacing gravel with MUDIPEL.

The ultimate aim is to achieve the Zero-Waste target. Meanwhile, the use of these ashes and sludges will significantly contribute to reducing the carbon footprint of railway projects, by replacing virgin gravel with waste that would otherwise end up in landfills.

After extensive laboratory tests at ZAG, various MUDIPEL mixtures were tested in small test fields. Subsequent to testing, the optimal mixture was selected; 70 % paper ash and 30 % paper sludge. The sludge content retains moisture in the recycled material, which allows longer transport distances from the production to the construction site.

The first earthworks took place at the end of August 2018. The test site is located in the municipality of Novo mesto and will see landslide stabilisation of an area with a length of 50 m near the Ljubljana – Novo mesto railway line. This initiative involved the recovery of 50 t of MUDIPEL. The renovation work includes the laying of foundations, construction of the drainage system and the installation of the gabions. The recycled MUDIPEL material is used prior to the construction of the gabions. MUDIPEL has to be compacted in layers with a thickness of not more than 20 cm at optimal water content and maximum density, in accordance with Slovenian regulation TSC 5.413.

This demonstration activity will validate the model through long-term monitoring and confirm the environmental friendliness of this type of retaining wall. The safety of the railway line will be dramatically improved as a result of this demonstration.

This circular-case being carried out in Slovenia is led by ZAG- Slovenian Building and Civil Engineering Institute. Other project partners include VIPAP VIDEM KRŠKO d.o.o., as a paper producer, and the construction company DH ( Dušan Holešek s.p.) as an SME.